For over 10 years, California-based Sunstall has been building clean and efficient solar energy solutions for their clients. With a business model based on continuous improvement, sustainability, and streamlining their work processes they were able to quickly expand from a West Coast startup to an industry leader. And as long-time Ganttic users, our resource planner has been helping Sunstall for much of their journey.

Recently we caught up with CEO Helge Biernath to discover their secret to success and how “Sunstalling the future” has become more than just a motto.

Novato, CA, USA

https://sunstall.com/

Solar Origins

Hollywood has always had a penchant for spectacular origin stories. So much so that one often forgets how in our own lives, random meetups can also be the start of something great.

Such was the case for Sunstall. Their company’s journey began as a chance encounter between German expats at an Oktoberfest celebration in northern California. Recognizing the potential of the burgeoning solar industry, they quickly turned an idea into a startup. And so Sunstall was born.

With a focus on ground mount solar installations, their idea took off. Now only a little more than a decade later, Sunstall’s team has had their boots on the ground in more than half of the US – from Hawaii to Massachusetts and everywhere in between. Expanding their client base and picking up good people wherever the next job takes them.

Which as it happens, can lead to its own set of challenges.

A Kaizen Approach to Sustainability and Growth

Success often depends on growth, but not all growth is necessarily sustainable. For Sunstall to transform from a startup into a solar construction firm with a nationwide presence, it was all about increasing efficiency every step of the way.

Luckily, CEO and co-founder Helge Biernath, (and yes, one of those initial Oktoberfest revelers) came into the company with a background in manufacturing. And he learned how to apply lean manufacturing principles popularized by Toyota, to more traditional construction project management. Systematizing every aspect, from logistics, to installation, to resources.

Knowing that resources are what brings projects to life, he wanted to find a way that put a focus on the people, tools, and machinery used in the solar installation process.

Helge Biernath (right) on-site.

Helge Biernath (right) on-site.

As Helge notes:

“From a planning perspective, we had to understand where our resources are, and how we can schedule them.”

Especially since most of their workforce and equipment was spread out to different parts of the country. This meant finding a management system that would bring together certain criteria:

- Resource-centric – with a focus on not only people but the equipment, vehicles, facilities, and tools as well.

- Online – that could be used to connect users from every part of the country

- Flexible – one solution that can be used by many different departments, for a wide variety of purposes.

- Focus on increasing efficiency – something that showed the gaps in the schedule, and which could help Sunstall easily fix the gaps.

Bringing Dispersed Teams and Resources Together

Sunstall first began using Ganttic in 2015 and have been “very happy” users ever since. So much so, that the number of resources they currently plan with has increased fivefold in that period of time. They originally adopted the resource planner to plan out and manage all their workforce and equipment for their upcoming construction projects. As well as a way to bring their dispersed project teams and departments together onto one central platform.

Since as Helge put it:

“Part of our business was always working from different locations, and not having to be based in the office. To do this, everyone needed to have the same information.”

But this decision wasn’t always necessarily due to geographical restrictions. Since they are in the green tech sector, Sunstall has always looked for ways to reduce their ecological footprint. And an online resource planning tool gave them that opportunity.

“Even before the pandemic, Sunstall used online platforms like Ganttic to conduct project management from anywhere in the country without people coming to a dedicated office. With it we could avoid coming together and reduce our environmental impact.”

So how do they do it?

A New POV

A typical day for Sunstall begins with a daily Ops meeting. It’s there that they take a look at the upcoming project resource schedule in Ganttic. Helge discloses how this helps them prepare for the day, since: “it’s useful to go through and look at every project. And it’s a good reminder of what’s going on and an opportunity for PMs to make changes.”

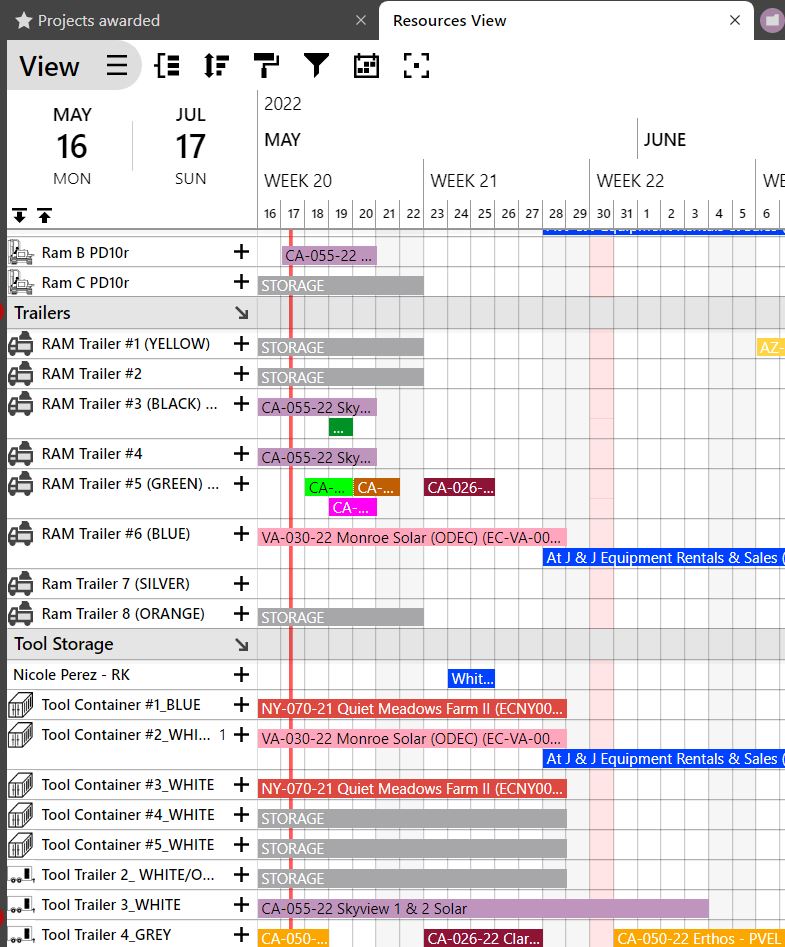

In these Ops meetings, the Sunstall teams utilize one of their favorite Ganttic features: Views. The use of which helps the teams to cycle between a Project View (where resources are grouped via their projects) and a Resource View (one where resources are grouped by their different departments and roles).

Sunstall’s Resource View in Ganttic.

Sunstall’s Resource View in Ganttic.

Different Views give a more complete story to their plans. And not only do they help the Sunstallers see when exactly the project is starting, but they can also begin to uncover what still needs to be fine-tuned ahead of project launch. It’s a unique feature not typically found in other Gantt charts. As Helge explains:

“Before I couldn’t find anything that showed both – the Resource View, which could be compared side-by-side to the Project View. The other options were typical Gantt charts that showed tasks, whereas Ganttic was more resource-centric. And it allowed us to jump back and forth between the two.“

Optimizing Cross Department Cooperation & Efficiency

Views are also a way for each department to coordinate between one another more efficiently. And help by optimizing their logistics process. That’s because with them:

“Different people from all over the company can look from different angles and get the most up to date information about their job.”

The Sunstallers on Ganttic include not only Project Managers, but HR, Ops managers, and those from Storage. With Views in tow, each department lead can easily find the upcoming projects planned that are relevant only to them. And hone in on those specifics.

For example, their Storage department can see what equipment is needed in the next few weeks, and begin prepping. This ensures that everything is ready to go when the time is right and cuts back on costly project delays. And helps them keep true to their mission.

“The planning tools are helping us to optimize the logistics between project locations, reducing waste and travel emissions!”

Sunstalling the Future

Right from the get-go Sunstall has stayed true to their goal of leading the future of renewable energy. They’ve been able to get where they are today by abiding by their own motto, “Sunstalling the future.” By continuously applying the latest in solar technology to their clients’ projects, they’ve been able to provide a cleaner more efficient energy source. This coupled with the application of lean manufacturing principles to the workflow, as well as investing in tools like Ganttic to help them bring projects to fruition, means they’ve set their own company as a leader in the sustainability sector and as a sustainable organization themselves.

Helge left us with one key piece of advice:

“It has to become a daily Kaizen process to improve a sustainable business. It’s not going to happen overnight and there is no silver bullet – and what sometimes seems obvious to improve sustainability might have collateral impacts. One must look at the whole picture.”

Maybe it’s not easy, and it may not be for everyone, but this way of thinking has helped Sunstall get to where they are today. And what does that mean for the future? Hopefully, not only a better place for their company, but for planet earth as well.

Learn more about how your own company can work more efficiently with our construction resource management software.