Managing resources is one of the toughest parts of engineering project management. While many project managers can handle scheduling people and timelines, things get trickier when non-human resources—like machines, tools, or specialized equipment—are part of the mix.

In industries like entertainment engineering, automotive, aerospace, or manufacturing, limited resources can turn even a well-planned project into a logistical puzzle.

This guest post comes from seasoned project manager Brad England, who shares real-world strategies for navigating resource-constrained projects in engineering-heavy environments.

The Real-World Impact of Resource Constraints

A few years ago I was consulting for an engineering firm in the entertainment industry.

They create mechanical devices for use in movies, theme parks, Broadway shows and many shows on the Las Vegas strip that rotate globes, drop superheroes from dizzying heights, and provide the audience with a seamless entertainment experience never realizing the amount of high-tech engineering and equipment that went into putting on the spectacle they were viewing.

While it’s an incredibly interesting arena to manage projects in, it also presents extreme difficulties in managing resources. Why?

Because resources aren’t just developers or engineers or machine workers that you can go out and hire tomorrow, train for two weeks and then put to work. Not quite that easy.

What you also have are the actual machines themselves, the resources that create the parts and pulleys and the cabling, and the wenches, and everything else that this company manufactures themselves in their shop to use on these projects they deliver on.

Speaking as a PM who has mainly dealt with human resource constraints in engineering project management, this was a new difficulty to overcome.

When Issues Arise

I was working closely with the general manager in this organization because the headaches were mostly his to deal with. The President and CEO of the organization – the creative force behind the company that was bearing his name – was a great salesman…traveling the world making new sales in other countries while production was going on back home in the US.

But the GM found himself trying to deliver on promises the CEO was making in these sales. This GM was trying very hard to deliver on promises made using a finite amount of equipment that was already booked solid and this presented interesting delivery issues.

What they were left with was a resource-constrained project scheduling issue that was threatening to turn this industry-leading state of the art organization into a company that couldn’t deliver the goods when promised.

Engineering projects’ resources can be difficult to plan – as they range from people to equipment.

Engineering projects’ resources can be difficult to plan – as they range from people to equipment.

The Solution

To remedy the situation, I created a new ‘standard’ project schedule templates that could be used as starting points for all the PMs in the organization.

I did this after carefully studying all current projects and several recently completed efforts. In doing so, I understood how they delivered on each project. As well as what some of the standard components were to each engagement. This information was then input into my resource plan.

I then inventoried all of the equipment – something that, unbelievably – had never really been done in a project management sense. And from that, I created a common resource pool that could be tied to all projects…allowing the GM to see what machines were overcommitted and under committed at any given moment in time.

Here’s a step-by-step breakdown:

Strategy 1: Build Standardized Project Schedules

To minimize bottlenecks, began building standardized schedules for different types of projects.

By creating templates based on the various job types, we were able to quickly adjust plans depending on the number of available machines. These templates also gave new project managers and engineers a solid starting point for project planning, accelerating onboarding and keeping everyone aligned.

Pro Tip: Standardized schedules reduce repetitive planning work, improve consistency, and make resource allocation faster.

Strategy 2: Conduct a Full Resource Inventory

Another critical step was getting a clear picture of what resources they actually had. This meant going beyond just people and listing out machines and other physical tools needed for project execution.

After compiling the inventory, the team could better identify which projects required specific resources—and when. This made it easier to proactively plan for resource sharing, reducing delays and avoiding scheduling collisions.

Bonus Tip: Include each resource’s availability, utilization, and constraints in your inventory for maximum planning accuracy.

Strategy 3: Use Centralized Resource Pool

The company also switched from siloed project planning to a centralized resource pool. This shift meant that project managers could see what other teams were working on and coordinate resource usage more effectively.

With this system in place, machines were less likely to be double-booked. And in cases where all machines were occupied, the visibility allowed teams to rearrange schedules or negotiate timelines without surprises. While also being able to put a capacity plan in place for the project’s duration.

Strategy 4: Use the Right Resource Management Software

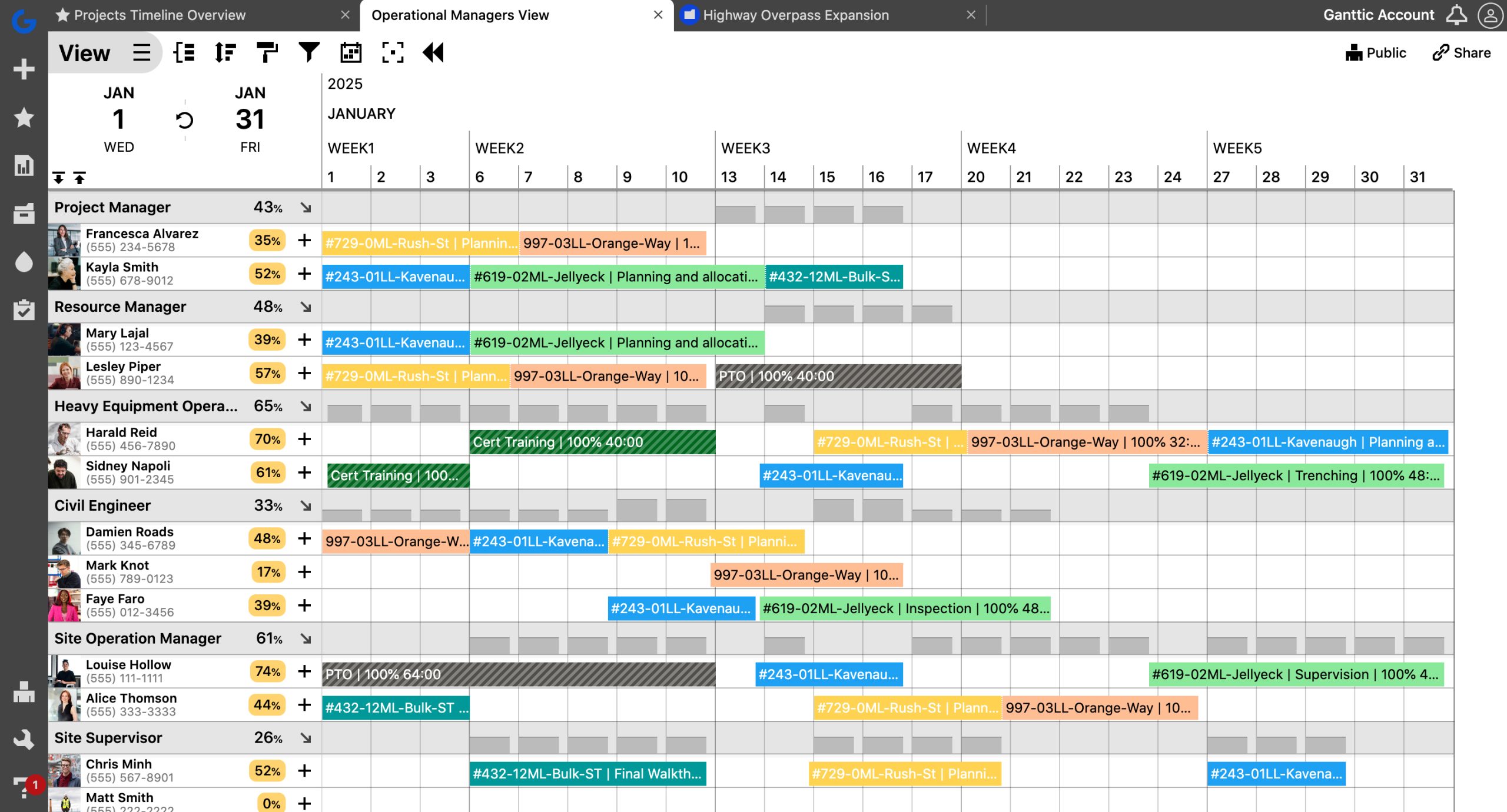

Finally, the company invested in resource management software (like Ganttic) to support their new processes. The tool allowed them to:

- Visualize resource allocation across all projects

- Forecast capacity

- Quickly adjust schedules when conflicts arose

Having this high-level overview made it easier to spot bottlenecks before they became major issues—and helped keep projects on track.

Final Thoughts: It’s All About Visibility and Structure

It’s nice to have lots of work. It’s usually easy – if your organization is thriving – to hire more human resources to perform work such as application development, testing, data integration, and research or engineering tasks. It might even seem like there are no resource constraints for project management. But don’t forget about the non-human resources.

Managing constrained resources isn’t just about having more—it’s about making better use of what’s available.

Especially if you’re working in a specialized industry where you may not be able to just go out and buy whatever you need to fill in the gaps. If something has to be designed and developed or crafted – as was the case for this organization if they wanted to meet higher demand – then the lead time for something like that may far exceed any learning curve you would need to build in when working solely with resources of the human type.

You can turn resource limitations into a competitive advantage and ensure smoother, more predictable project execution with a strategy and resource management software for engineering firms.

Ganttic for Engineering Resource Management

Ganttic is a resource planner used by engineering teams worldwide for project resource management.

Ganttic is a resource planner used by engineering teams worldwide for project resource management.

Whether you’re managing people, equipment, or both, Ganttic gives you the tools to schedule, allocate, and optimize your resources with confidence. Visualize availability, prevent bottlenecks, and stay on top of every engineering project—no matter how complex.

👉 Try Ganttic free and see how better planning leads to better results.

This is a guest post from Brad Egeland who is an IT/Project Management consultant and author with over 25 years of software development, management, and project management experience leading initiatives in Manufacturing, Government Contracting, Gaming and Hospitality, Retail Operations, Aviation and Airline, Pharmaceutical, Start-ups, Healthcare, Higher Education, Non-profit, High-Tech, Engineering and general IT. Brad is married, a father of 9, and living in sunny Las Vegas, NV.